Electronic Manufacturing Services (EMS)

Innovative solutions for high-quality electronic product development.

Innovative solutions for high-quality electronic product development.

Ensure the product design is optimized for efficient manufacturing. This includes selecting standard components, minimizing complexity, and planning for scalability.

Establish a reliable supply chain for electronic components to avoid delays and ensure quality. Consider multiple sources for critical components to mitigate risks.

Implement rigorous quality control processes, including automated testing (ATE), in-circuit testing (ICT), and functional testing to ensure the product meets required standards.

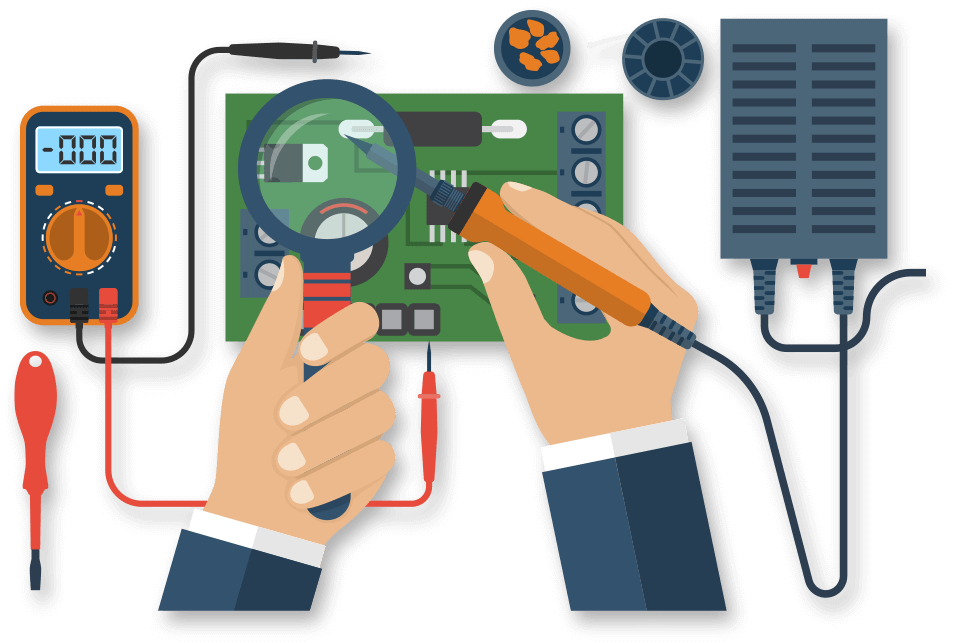

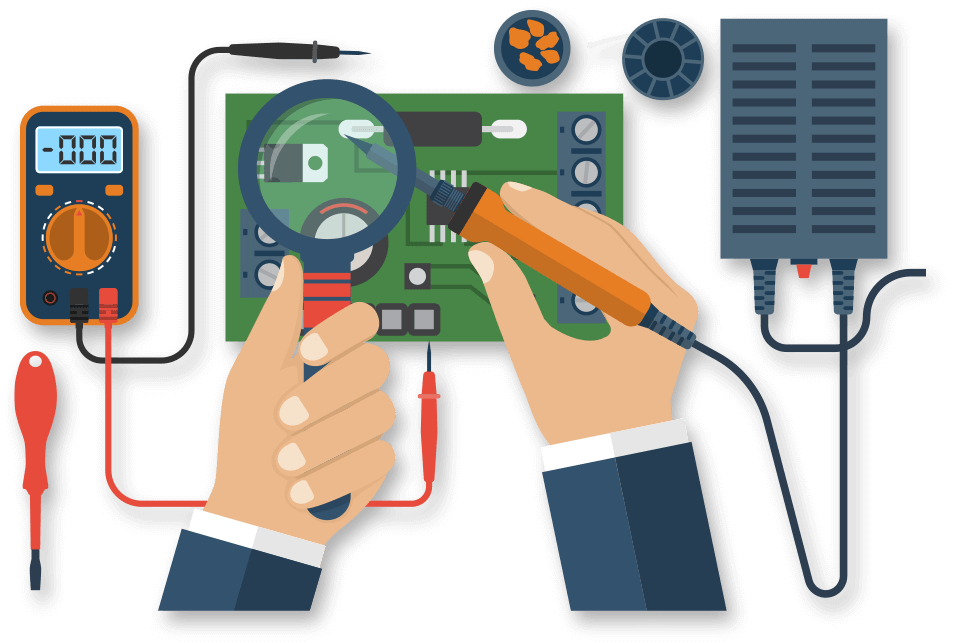

Focus on accurate placement and soldering of components during PCB assembly. Use advanced techniques like Surface Mount Technology (SMT) for high-speed, high-precision manufacturing.

Build and test prototypes to validate the design before moving to mass production.

Adhere to relevant industry standards and certifications such as ISO, FCC, CE, or RoHS to ensure the product is legally compliant and safe for use.

Leverage automation, robotics, and IoT technologies to improve production efficiency, reduce costs, and maintain consistency in manufacturing processes.

Incorporate eco-friendly practices by reducing e-waste, recycling materials, and designing energy-efficient products to meet global sustainability standards.

Gather customer feedback post-deployment and implement iterative improvements in the manufacturing process to enhance product quality and reliability.